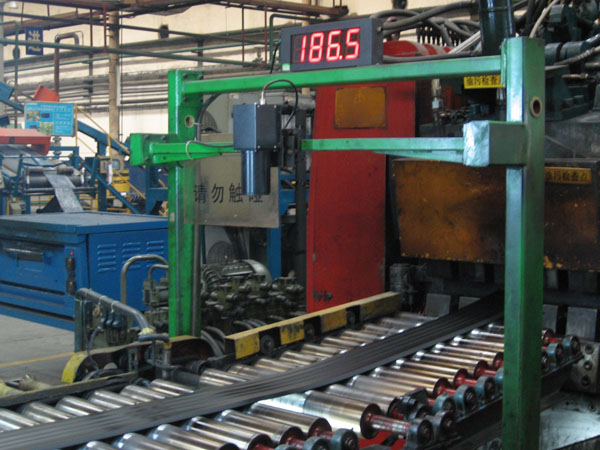

Tread (side) width measurement, speed control system

Tread (side) width measurement, speed control system

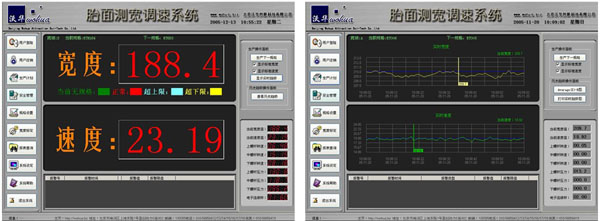

The system is to utilize CCD intelligent width gauge for extrusion measure the width of the tread (side), and compared with standard width tread (side), by changing the contraction speed roller motor, adjust line drawing speed, to ensure the system of lead width meet the technological requirements, thus the system will realize the measurement of the width of the derivation, record and control.

Main Functions:

1. Automatic measurement, display and record of the width of the extrusion tread (side).

2. Compare the width of the tread (side) with the standard value, and judge the quality grade of the product.

3. Adjust the speed of linkage line according to the measured data of CCD width measuring device.

Main technical indicators:

1, CCD width measurement accuracy: ±0.5mm.

2, tread width control accuracy: ±1mm; Accuracy of lateral width control: ±1mm (average of total width).

3. Data storage time: 5 seconds, that is, all data is stored every 5 seconds. 5 seconds is a storage cycle.

.html)

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Hotline:400-818-6918

Hotline:400-818-6918

Web:www.wohuakeji.com

Web:www.wohuakeji.com