Automatic Measurement System for Tread (side) Section thickness (off-line)

Model Number: WH-CH0S1-30

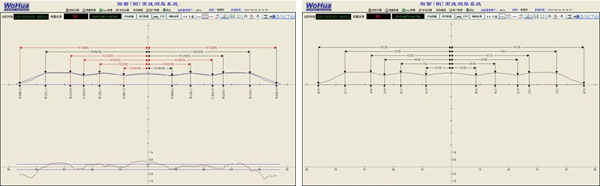

Product synopsis: using laser sensor measuring the thickness of the tread (side), when the thickness of the measured object changes, the launch of the analyte laser to the laser generator, after reflection light displacement changes will take place on the laser receiver position, through the calculation of geometric variation of analyte that thickness and the thickness of the signal displayed in digital or curve way.

The mechanical structure of the system adopts C-type installation mode, the two sensors are fixed on the lower end of the C-type frame, and the scanning function is realized by translating the C-type frame, so as to complete the whole tread (side) scanning measurement.

The thickness, contour and width of the cut tread (side) are measured, displayed and counted in various forms.

Main Functions:

1. Automatically measure the thickness of the extrusion tread (side) and form the profile of the section.

2. Automatic measurement and display of the width of the extrusion tread (side).

3. Compare the thickness profile, width and deviation of the tread (side) with the standard value, make a judgment on whether the mouth plate is qualified, and correct it.

Technical indicators:

| The serial number | Content of technical requirements | Technical indicators |

| 1 | Thickness measurement range | 0~30mm |

| 2 | Thickness measurement accuracy | ±0.05mm |

| 3 | Width measurement accuracy | ±0.5mm |

| 4 | Working voltage | 220V 50Hz |

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Hotline:400-818-6918

Hotline:400-818-6918

Web:www.wohuakeji.com

Web:www.wohuakeji.com